-

Time:4/2/2025

-

Time:3/31/2025

-

Time:2/19/2025

- CONTACT US

- [email protected]

Classification and Advantages of Plastic Cardboard Box

Time:12/24/2019

Time:12/24/2019 826

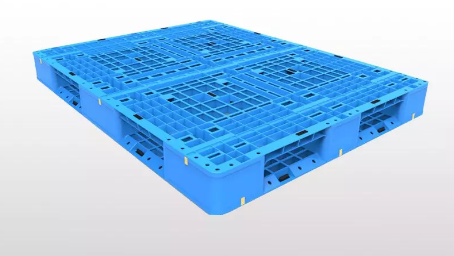

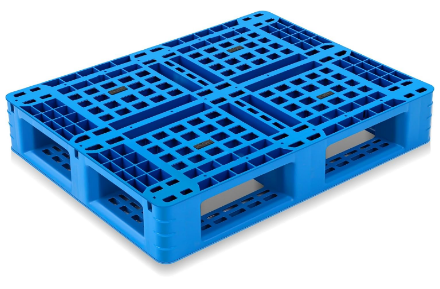

826Plastic pallet box, also known as plastic pallet box, is made of bottom pallet and box.

Plastic card box is classified into:

1. Folding pallet box style, the bottom bracket is connected with the box wall, which can be folded to the internal buckle type when the box is empty, greatly reducing the storage volume and logistics volume when the box is empty.

2. Combination style (the bottom is the card board and the upper part is the removable box wall)

3. Integrated style (the bottom card board and the box are integrally formed and connected, and sinor provides injection mold manufacturing.)

Large foldable cardboard box

Large foldable pallet box is designed to reduce storage volume and logistics transportation cost when empty. Foldable cardboard box inherits the consistent design of bearing capacity (dynamic load 0.75T; static load 3T) of closed cardboard box products. HDPE has strong impact resistance and long service life through foaming treatment. There are four long and short side plates of different sizes around the large folding box, the base of tray style and the small pick-up door designed on the side door, which are assembled by dozens of parts and components. At the same time, they are manufactured by eight sets of molds.

1. The products are beautiful, environmental friendly, durable, hard in quality, high in chemical stability, nontoxic and tasteless. They are the best choice for logistics and warehousing.

2. The service life of plastic cardboard box is about 10 times longer than that of wooden box.

3. Plastic cardboard box is much lighter than the same type of wooden box and metal box. It adopts integrated molding, so it has better performance in handling and transportation.

4. Plastic card box can be cleaned with water at any time, beautiful and environmental friendly.

5. It can be widely used for the storage and turnover of liquid and powder goods. It is widely used in petroleum, chemical industry, medicine, food and other industries.