-

Time:4/2/2025

-

Time:3/31/2025

-

Time:2/19/2025

- CONTACT US

- [email protected]

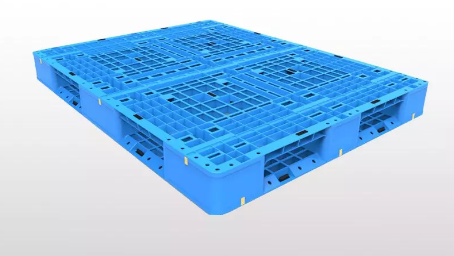

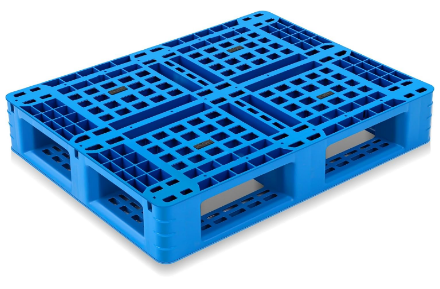

Daily Maintenance and Use of Plastic Pallets

Time:6/13/2019

Time:6/13/2019 1444

1444When using, we should try our best to avoid strong impact, including the strong collision between the pallet on the ground and heavy goods and pallets. In addition, we should standardize the forklift driver's forklift movement. There are many pallets, which are actually caused by the improper operation of the forklift driver and the strong impact of the forklift leg on the pallet. If a mechanical forklift is used, try to adjust the leg of the forklift to the outside of the pallet, so as to avoid two forklift legs in the middle of the pallet of the forklift, resulting in uneven force breaking of the pallet.

First of all, the material of plastic pallet is usually PE or PP or the mixture of these two materials, so we usually say that plastic pallet can be welded, can be welded with ultrasonic welding machine. The principle is to use the high frequency vibration of the ultrasonic wave to heat the fusion surface of two materials by high frequency friction, while the plastic has poor thermal conductivity and slow heat dissipation, which results in heat accumulation, and the pressure of the ultrasonic welding machine makes the two plastic pallets weld together perfectly. At present, ultrasonic welding can replace glue for bonding because of energy saving and environmental protection, so the application fields are more and more extensive, such as electronic industry, automobile industry, smart home industry and so on.

Ultrasound welding is a fast, efficient and pollution-free welding method. How to ensure the perfection of plastic welding? First, material selection: the welding strength of two plastic pallets of the same material is higher than that of two plastic pallets of different materials; second, the design of fuse guide: the design height and width of fuse guide have certain requirements, depending on what effect you want to achieve, such as whether to require air tightness; third, the contact surface: it is better not to paint or spray on the welding contact surface, so on. It will lead to low welding strength, which can not meet the reliability of the product. Fourth, spark pattern design: if necessary, the contact surface can be designed into spark pattern to increase friction coefficient and welding strength.