-

Time:4/2/2025

-

Time:3/31/2025

-

Time:2/19/2025

- CONTACT US

- [email protected]

Products News

Development Status of Plastic Pallet

Time:11/19/2020

Time:11/19/2020 1032

1032Share:

The role of pallet in modern logistics is self-evident, more and more places can use pallet, so what is the specific market now? Follow aceally。

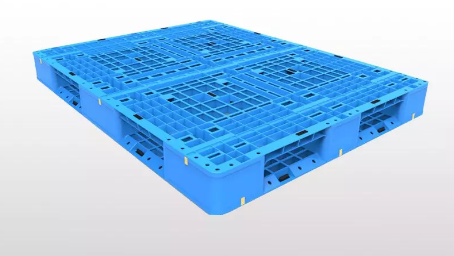

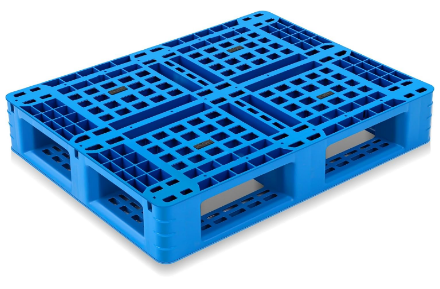

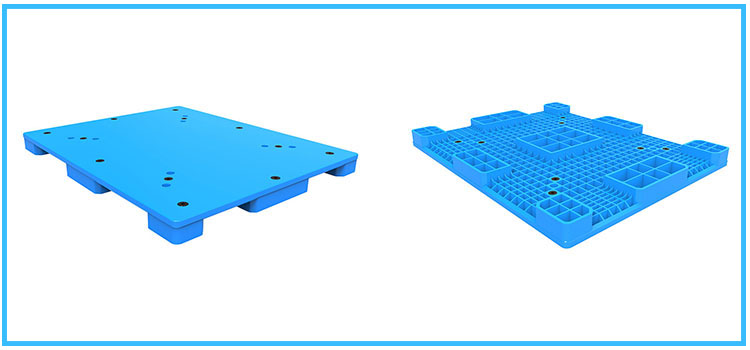

Firstly, the performance of plastic pallets is superior. Secondly, in recent years, the country has increased the control of deforestation, resulting in a sharp rise in wood costs. In addition, the European and American requirements for wooden pallets are more and more stringent, which stimulates the use of plastic pallets. Thirdly, the processing equipment for plastic pallets is highly automated, with large output and flexible design Better meet the personalized needs of customers.

According to the introduction, the plastic tray is made of PE or PP through injection molding, blow molding and other processes. At present, it has been widely used in machinery, electronics, food, medicine, chemical industry, clothing and other industries. Compared with wooden pallets, plastic pallets are characterized by good integrity, sanitation and cleanness, easy washing and disinfection, light weight, corrosion resistance, acid and alkali resistance, moisture and moth proofing, mildew resistance, impact resistance, etc., and its service life is long. In general, the service life of plastic pallet is 5-7 times of that of wooden pallet. Although the price of plastic pallets is relatively high, the cost of using them is lower than that of wooden pallets. Plastic pallet is the best comprehensive performance of the pallet varieties.

The first is that the plastic pallet enterprises have carried out process reform by adding steel parts, which makes the load capacity of plastic pallets increase and the scope of use is widened;

Second, because of the advantages and necessity of using pallets for beer, beverage, dairy products and other products with high quality and standardized packaging, the demand for plastic pallets by manufacturers is growing rapidly;

Third, the plastic pallet processing design is flexible, which can better meet the customized needs of customers.