-

Time:4/2/2025

-

Time:3/31/2025

-

Time:2/19/2025

- CONTACT US

- [email protected]

Products News

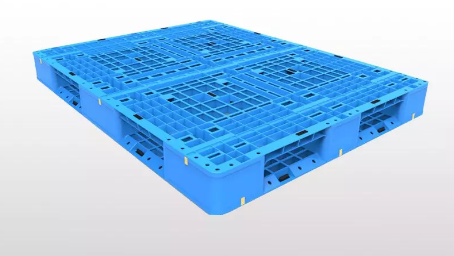

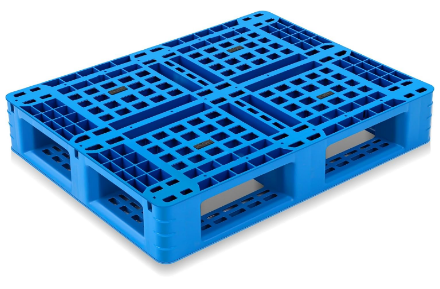

Do You Know the Cause of Discoloration of Plastic Trays?

Time:9/19/2019

Time:9/19/2019 1228

1228Share:

Why do plastic pallets discolor? After a period of use, the discoloration of plastic pallets is usually caused by aging (degradation), because there are unstable side groups on polypropylene, especially in light conditions. This is due to material aging or degradation, usually involved in light stabilizers. Because PE has no side base, it is not common to treat or use yellowing early. PVC will turn yellow, and the formulation of the product is relatively large.

The primary reason for whitening is oxidation. Some plastic pallets have simple surface oxidation and need to master surface treatment.

In addition to the harmful additives and impurities in the system, mainly caused by aging, in addition to appropriate antioxidant systems and anti-ultraviolet agents can improve the yellowing of PE, PP, but many hindered phenolic antioxidant systems themselves will bring slight yellowing, there are also some antioxidant systems and anti-ultraviolet agents have resistance, so use carefully. Participation in polymer lubricants is mainly to form movable polymer fluoropolymer film on the machine wall, improve the extrusion function of polyolefin resin, extrusion pressure and processing temperature, improve product quality, improve productivity, reduce production costs, reduce or eliminate melt rupture and reduce scrap rate.

When plastic trays are not used, we should store them at home to avoid direct sunlight and reduce color aberration.

Measures to prevent photochromism include isolating ultraviolet rays, changing the structure of absorption components, isolating oxygen and capturing free radicals, destroying the structure of discolored substances and removing discolored precursor cells.

In order to prevent biological discoloration, change or destroy environmental factors, such as temperature, humidity, pH value, oxygen and nutrients suitable for microorganisms or organisms, such as water mist preservation, plastic sealing and chemical treatment.

The primary reason for whitening is oxidation. Some plastic pallets have simple surface oxidation and need to master surface treatment.

In addition to the harmful additives and impurities in the system, mainly caused by aging, in addition to appropriate antioxidant systems and anti-ultraviolet agents can improve the yellowing of PE, PP, but many hindered phenolic antioxidant systems themselves will bring slight yellowing, there are also some antioxidant systems and anti-ultraviolet agents have resistance, so use carefully. Participation in polymer lubricants is mainly to form movable polymer fluoropolymer film on the machine wall, improve the extrusion function of polyolefin resin, extrusion pressure and processing temperature, improve product quality, improve productivity, reduce production costs, reduce or eliminate melt rupture and reduce scrap rate.

When plastic trays are not used, we should store them at home to avoid direct sunlight and reduce color aberration.

Measures to prevent photochromism include isolating ultraviolet rays, changing the structure of absorption components, isolating oxygen and capturing free radicals, destroying the structure of discolored substances and removing discolored precursor cells.

In order to prevent biological discoloration, change or destroy environmental factors, such as temperature, humidity, pH value, oxygen and nutrients suitable for microorganisms or organisms, such as water mist preservation, plastic sealing and chemical treatment.

In order to avoid enzyme discoloration, reduce enzyme activity and isolate oxygen, such as acid-base treatment to adjust the pH value, according to boiling, high-frequency heating to change cholesterol characteristics, antioxidant inverted PHENOLASE activity, water to isolate oxygen.