-

Time:9/2/2025

-

Time:8/4/2025

-

Time:7/2/2025

-

Time:6/10/2025

-

Time:5/5/2025

- CONTACT US

- [email protected]

Products News

How to Distinguish Tthe Quality of Parts Box?

Time:8/19/2020

Time:8/19/2020 1084

1084Share:

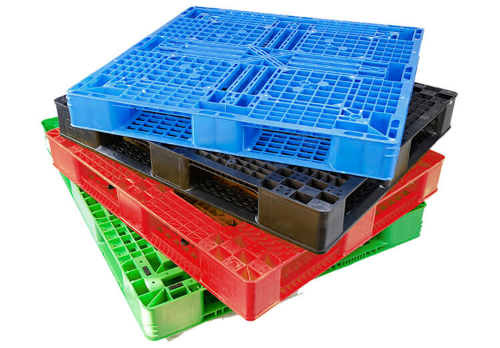

Plastic parts box is widely used, but the turnover goods are more convenient, stacked neatly and easy to manage. The reasonable design and good quality of the parts box make it easy to be used in the transportation, distribution, storage, circulation and processing of factory logistics, which is convenient for enterprise management.

So how do we distinguish between parts boxes? Here, aceally will briefly introduce the five elements to identify the quality of plastic parts boxes.

1.Good plastic part of the box has good bearing capacity to prevent the goods from deformation after long-term stacking, so as to prevent the box from being broken due to accidental impact and damaging the product.

2.A good plastic parts box has good chemical and physical properties, and the hot summer will not cause plastic deformation of the box part and the concave convex plastic deformation of the tray box

3.A good plastic parts box has good aging resistance, which mainly depends on whether it is made of pure polyethylene and whether there is relevant inspection certificate.

4.Good plastic accessory box has good hygiene. Plastic accessory box is a large part of food processing industry. This industry needs accessory box to ensure that there is no poison and peculiar smell. At present, the country has strict requirements on the food industry. We should choose some products from large manufacturers, and the quality and hygiene factors can be well solved.

5.Good plastic parts box has good corrosion resistance, plastic parts box should have good corrosion resistance, and chemical properties will not be changed due to strong acid and alkali.