-

Time:9/2/2025

-

Time:8/4/2025

-

Time:7/2/2025

-

Time:6/10/2025

-

Time:5/5/2025

- CONTACT US

- [email protected]

Nine Factors Affecting the Quality of Plastic Pallet

Time:12/16/2019

Time:12/16/2019 1029

1029In the production activities we are engaged in, it is inevitable to use plastic pallets to hold items. But, do you know? There are also quality differences in plastic pallets. Poor plastic pallets may bring certain losses to our production. In order to ensure safety, we still need to choose good quality plastic pallets. Next, aceally tells you the nine factors that affect the quality of plastic pallets to let you know more.

1. Equipment: it is very important to choose what kind of injection molding machine and how many tonnage of injection molding machine to produce. Different from tonnage box, plastic pallet needs to be produced by larger injection molding machine to ensure the quality of plastic pallet is not affected.

2. Technology: plastic pallets need to be produced by larger injection molding machines. Therefore, plastic pallet manufacturers believe that the operation of large injection molding machine must be skilled master. Otherwise, the qualified rate of plastic pallet products is low and the scrap rate is high. Affect the quality and productivity of plastic pallet.

3. Raw materials: it is no exaggeration to say that the quality of raw materials used in the plastic tray will directly affect the overall quality of the plastic tray. At present, PP or PE materials used in plastic tray are divided into original new materials, sub brand new materials and nozzles. There are several materials, materials, recycled materials and modified materials. Using different raw materials, the quality of plastic pallet is very different.

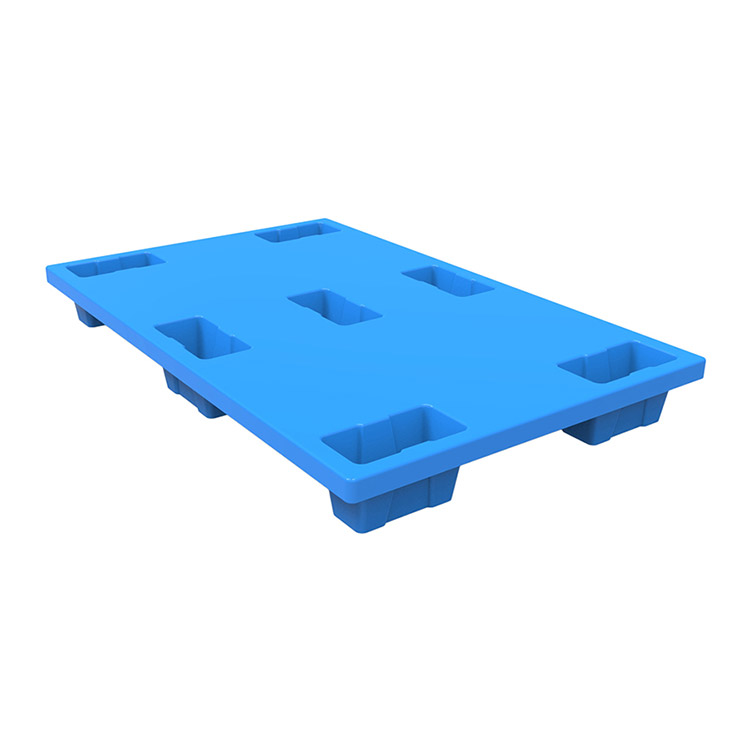

4. Structure: the manufacturer of plastic pallet tells you that the structure of each manufacturer is different for the same size of plastic pallet, such as the size and density of grid; the distribution and arrangement of ribs, etc., which need long-term use as a reference.

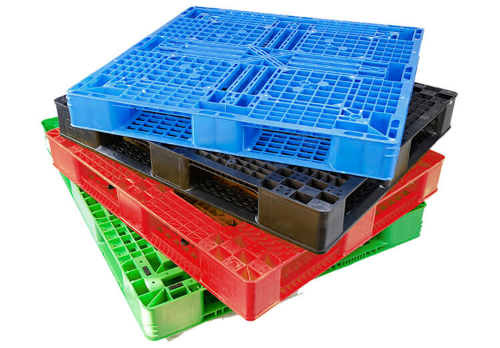

5. Type: there are many types of plastic pallets. At present, there are Sichuan tray, field tray, nine foot tray, flat tray, grid tray, double-sided tray, etc. Different types of pallet application industry are different, and the price is also different.

6. Modification: in some special industries, such as the refrigeration industry, plastic pallets need to withstand a low temperature of at least - 20 ° C; in the chemical industry, plastic pallets need to be corrosion-resistant; the plastic pallets used in these industries need to add some relatively modified additives to meet the needs of the industry.

7. Mold: the manufacturer of plastic tray tells you that there are many injection mold manufacturers, but there are not many plastic tray molds. Most of them are made of water basket, water tank and other molds. The load capacity of plastic pallet is tons. The water basket weighs in pounds, not at all.

8. Accessories: in order to increase the load of plastic tray, the usual injection tray will be built with steel pipe. For example, the dynamic load of the original integrated plastic pallet is 1 ton, the static load is 3 tons, and the customer industry needs 1.5 tons of dynamic load. Without changing the size of the model, the built-in steel pipe can perfectly meet the needs of customers.